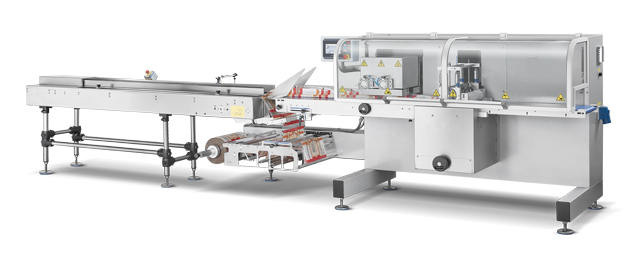

The horizontal flow wrappers are offered in a wide range for many industries from food sectors to non-food sectors. Chocolate bars, candies, sand cakes or sausage and cheese products are packed in a self-service manner, they are used for packing blisters, masks and Petri dishes or for packing electrical parts or baseboards. The flow pack machines ensure product protection and comply with strict legal hygiene regulations.

Modern wrapping materials for flow-pack wrapping meet all, sometimes extreme, requirements: cellophane, polypropylene, PE-coated paper, PP-coated aluminium as well as all other heat- and cold-sealable wrapping materials and polyethylene are used. They can all be processed economically with the horizontal flow wrapping machines from Kopp Verpackungssysteme.

Our horizontal flow wrappers: GEMINI-INT – AURIGA – CARINA

The flow wrappers offered especially for the food sector provide the possibility of gas flushing shortly before the closing process. The packaging machines can be loaded manually as stand-alone machines or be integrated into a production line. A compact design saves floor space. Adjustable forming shoulders allow an easy and quick product change and offer a large format range. The flow wrappers are customized to meet individual production, economic and package style requirements.