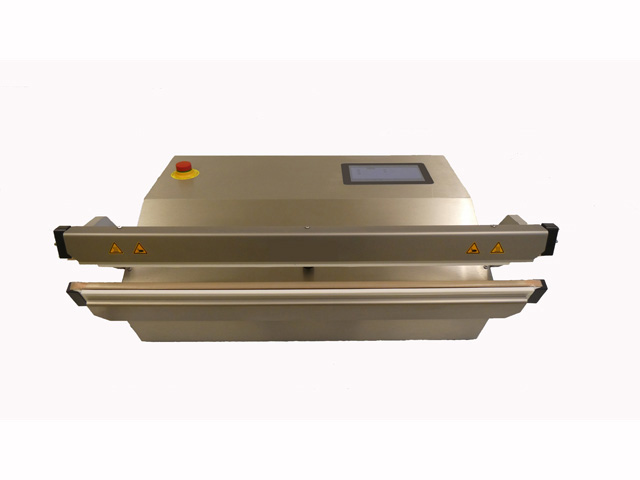

Impulse sealers are used in many branches and in different business divisions. Therefore, you find a great choice of various machines designed for packing goods in film materials. All devices produced by KOPP Verpackungssysteme are designated for use in industry and commerce. The units are provided with sealing bars up to a length of 1,020mm. Sealing widths of 3mm, 5mm and 8mm depending on the device used are possible. Films and bags made of thermoplastic material such as polyethylene (LDPE), polypropylene, and so on can be handled. Film sealing units of the Med series are especially designed for making sterilized packs and closing peel bags according to ISO 11607. They are used for primary as well as secondary packing for example for surgical instruments, for implants and catheters, for tubes, infusion accessories, and so on.

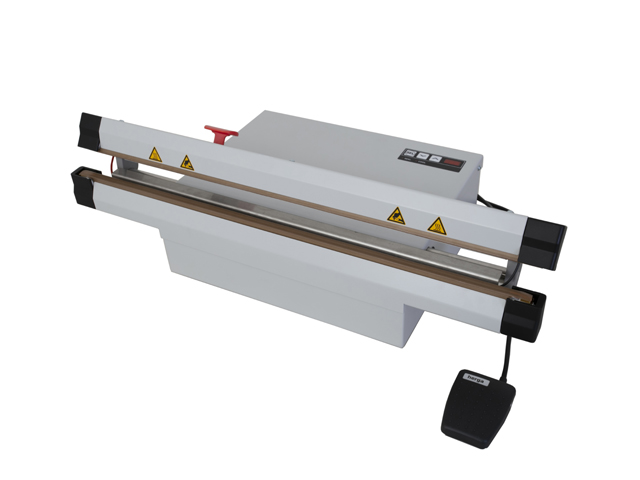

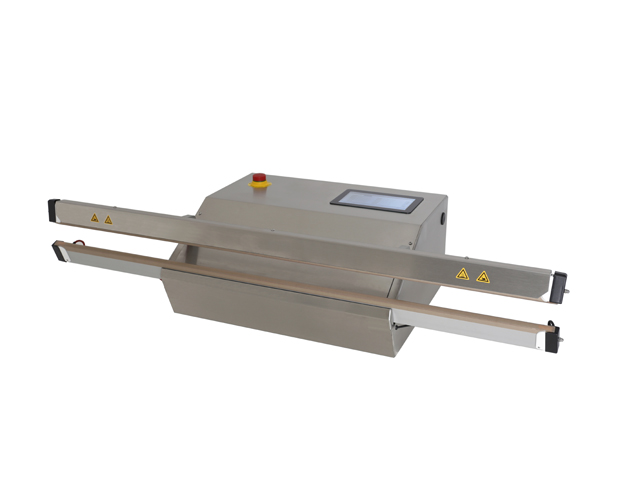

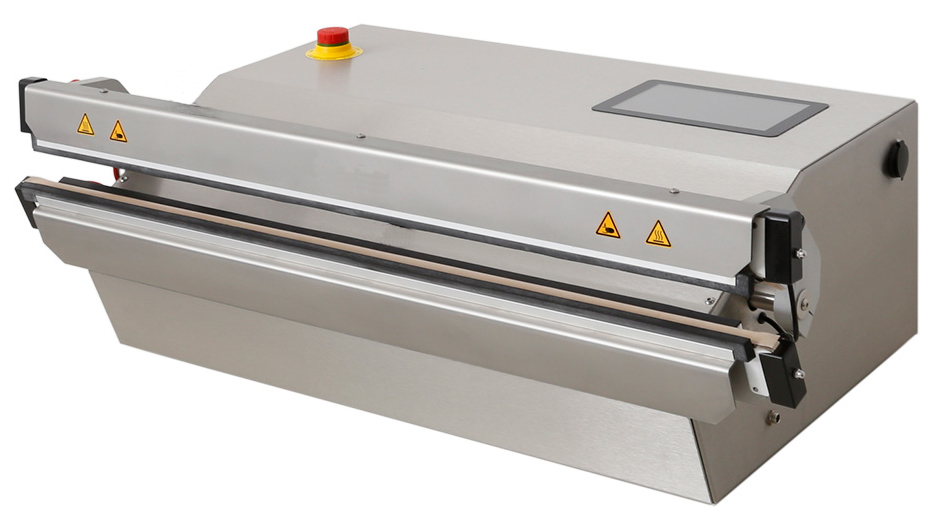

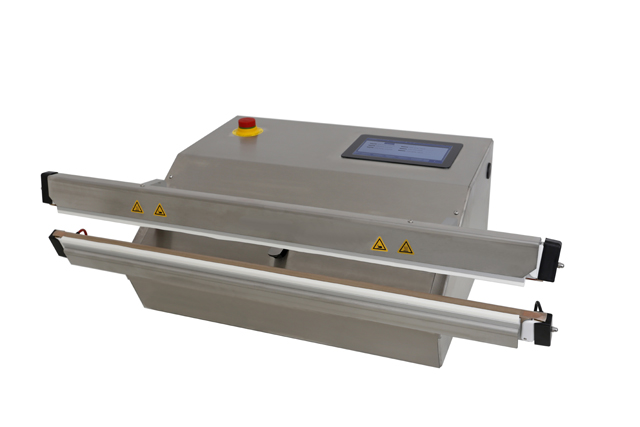

Not only sealing weld and film material but also handling and precision are important when comparing the various devices: There are machines from simple tabletop units with visual display, all-purpose film sealing devices with potentiometer control, magnetic closure and electric foot pedals up to sealing units with temperature control or even with control functions for validation of the sealing.

The modern film sealing units with real temperature control are particularly interesting. A microprocessor monitors the temperature in the heating tape and adjusts it if necessary. This ensures a consistent welding quality. Overheating of the heating tape and burning of the PTFE tapes are no longer a problem. Thus, downtimes and follow-up costs are reduced to a minimum.