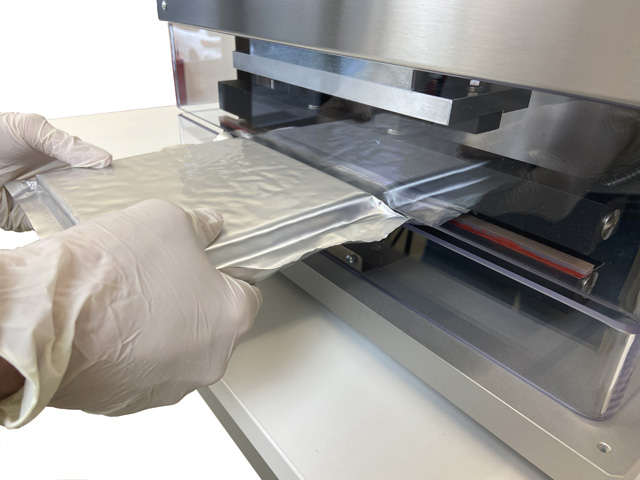

The importance of electrochemical storage systems is constantly increasing. The lithium-ion battery plays an important role here and has established itself in almost all areas of application in recent years. Much research is also being carried out in the field of solid-state batteries, as these have the potential for higher energy density and faster charging speeds. The HSGS heat sealer is used in battery production for sealing pouch foils for batteries (rechargeable batteries), pouch bag cells, battery components or for sealing tabs in research and development as well as in prototype production and small series production.

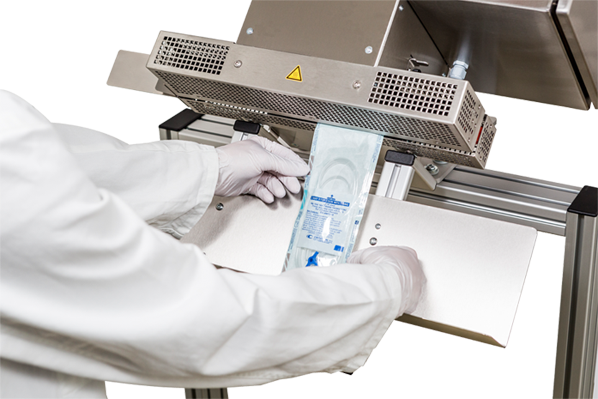

It is also used for sealing coated cardboard riders, bag riders, saddle labels, rider labels etc. as an alternative to staples or for sealing cardboard blisters.

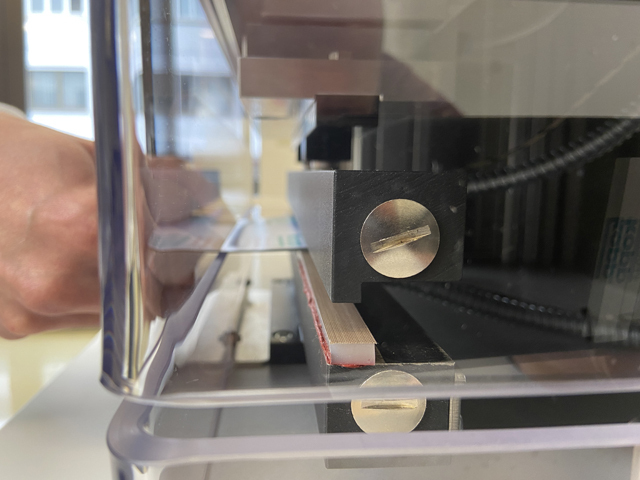

The clever design of the machine provides plenty of space behind the sealing bars. This makes it possible to easily seal bags or cardboard tabs with a large excess length above the sealing.