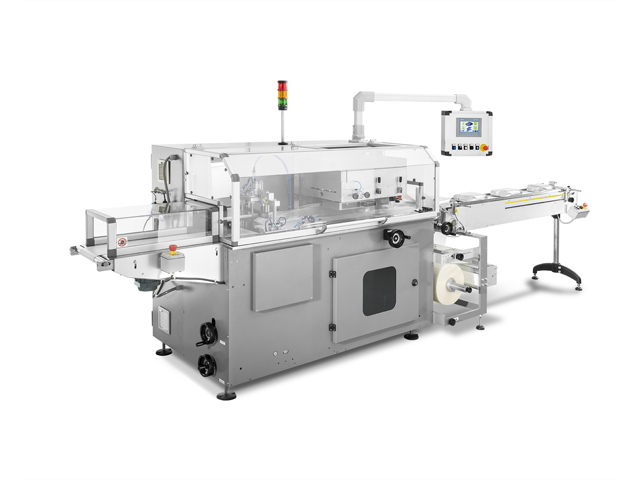

When deciding on automated packaging of products in film, manufacturers have the option of choosing between different packaging machines and different methods. If rectangular products shall be protected and attractively packaged, overwrapping machines, also known as cellophane wrappers, come into question for this application. With cellophane wrappers, the film is wrapped tightly around the product with an exact fold pattern. A wide variety of products from the food and non-food sectors are packaged in this way, such as chocolates or biscuits, perfume, index cards, stacks of paper, tea boxes and much more. Depending on the product, the fold wrap preserves the aroma, protects against humidity, extends the shelf life and visually enhances the packaged goods.

Suitable packaging materials include various heat-sealable and weldable flat films such as polypropylene, polyethylene, laminate and aluminium foils, as well as coated and uncoated types of paper. The overwrapping machines convince with optically perfect packaging results, but also with favourable manufacturing costs at low energy consumption. Cellophane machines are used fully automatically or semi-automatically, depending on the product, the packaging quantity and the desired packaging output. The product infeed can be continuous or intermittent in line with or to the side of the machine.

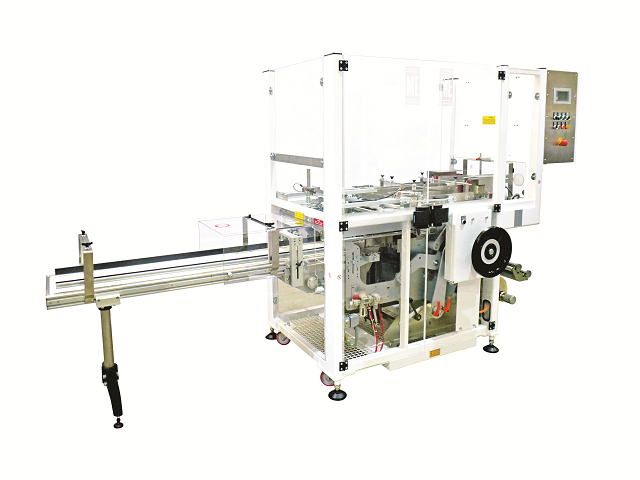

If the products from industry and trade are to be packaged with flow wrapping machines, then there is a choice of vertically or horizontally operating systems. In both processes, flat films are processed, which are formed into a tube via a forming shoulder, then filled and finally sealed. A typical feature of flow wrapping packaging is the fin seam. These wrapping machines are suitable for many products from different industries, such as the food industry, medical technology, the automotive industry, the pharmaceutical sector and many others. Packaging machines can be operated as stand-alone machines or be integrated into a production line. Depending on the machine, the film is fed in from below or from above in the case of horizontal machines and a wide range of formats can be processed thanks to adjustable forming shoulders. The vertical form, fill and sealing machines are perfectly suited for packaging bulk goods, as well as free-flowing or powdery products.