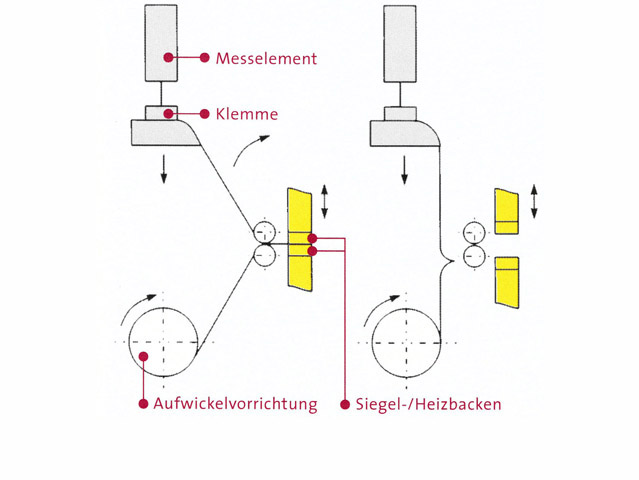

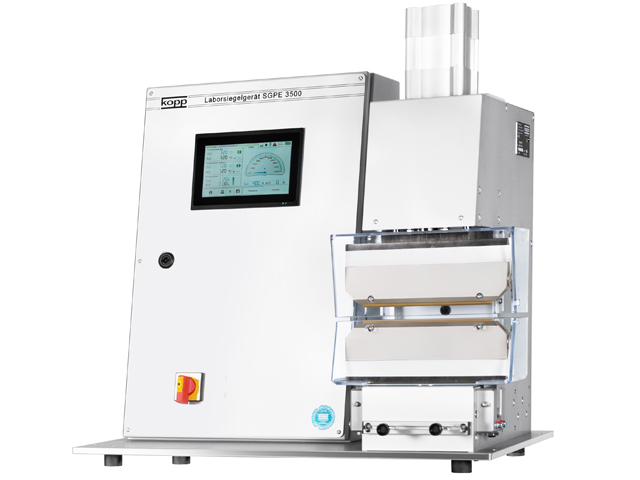

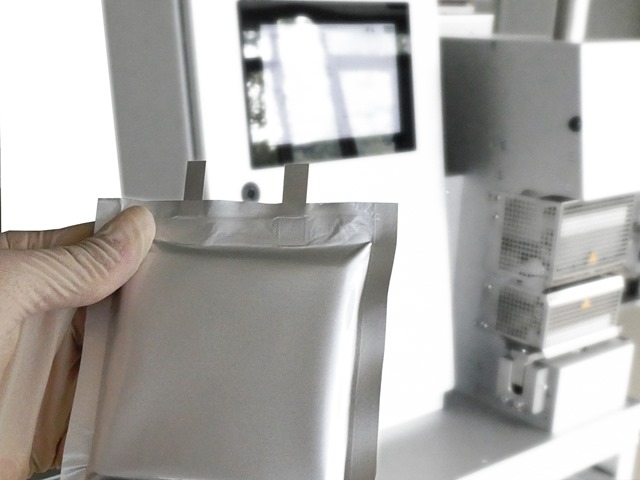

The Labormaster hottack tester has its permanent place in packaging material development for flexible packaging, i.e. for classic plastic films, laminates and composites as well as for coated papers or new sealable, recyclable packaging materials and compostable packaging materials.

During production, the Labormaster is used in the manufacture and refinement of packaging materials for quality assurance.

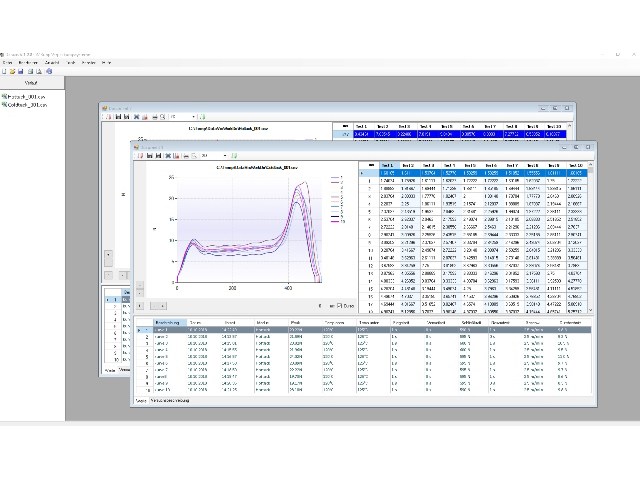

In addition, the testing device helps quality control and quality assurance in checking the sealing properties, heat sealability and in determining the optimal processing parameters (sealing window).